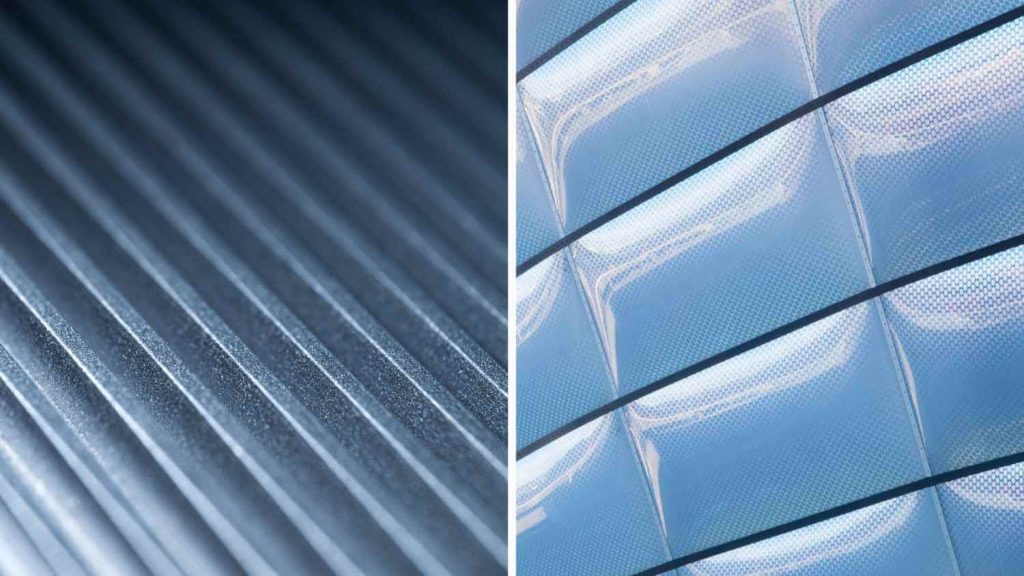

When selecting materials for skylights, roofing panels, or other glazing applications, two options frequently top the list: polycarbonate and fiberglass. Both offer distinct advantages over traditional glass, but understanding the difference between polycarbonate and fiberglass is essential for choosing the right material for your project.

This guide breaks down the polycarbonate vs fiberglass comparison across key factors—durability, light transmission, cost, and applications—so you can make an informed decision.

Introduction to Glazing Materials

Glazing materials provide natural light, thermal insulation, and impact resistance, enhancing comfort, safety, and energy efficiency. Polycarbonate sheets, available as solid or multiwall forms, are known for high impact resistance and thermal insulation, making them ideal for outdoor use. Fiberglass is a composite of glass fibers in resin, offering good tensile strength and durability. Understanding their differences helps select the best option for skylights, canopies, or industrial windows.

Quick Comparison: Polycarbonate vs Fiberglass

| Feature | Polycarbonate | Fiberglass (FRP) |

| Impact Resistance | Excellent, high strength (virtually unbreakable) | Good (can crack under heavy impact) |

| Light Transmission | Up to 90% clarity | 50–80% (diffused light) |

| UV Resistance | Excellent with coating | Moderate (may yellow over time) |

| Chemical Resistance | Good | Excellent |

| Weight / Installation | Lightweight, easy to install | Heavier, more effort to install |

| Lifespan | 15–25 years | 20–30 years |

| Cost | Higher upfront, cost-effective long term | More affordable |

| Best For | Clarity, impact protection | Chemical environments, budget projects |

What Is Polycarbonate?

Polycarbonate is a high-performance thermoplastic known for exceptional strength and optical clarity. Used in skylights, greenhouses, security glazing, and roof panels, it is 200 times stronger than glass and used in bulletproof windows. Polycarbonate sheets often include a UV-protection layer blocking over 99% of harmful UV rays, enhancing outdoor durability. Being about 40% lighter than fiberglass, polycarbonate is easier to handle and install. Its long lifespan and recyclability make it an environmentally friendly choice.

What Is Fiberglass (FRP)?

Fiberglass reinforced panels (FRP) combine glass fibers with resin, creating a strong composite used in industrial roofing, agricultural buildings, and chemical-resistant environments. Fiberglass can be molded into various shapes and is flame-resistant. It excels in chemical resistance, ideal for industrial and agricultural settings, including swimming pools and chemical storage. While less clear than polycarbonate, fiberglass offers durability at a lower price point.

Polycarbonate vs Fiberglass: Detailed Comparison

Impact Resistance and Strength

Winner: Polycarbonate

Polycarbonate absorbs impacts by flexing and returning to shape, avoiding cracking. Fiberglass is more brittle and can shatter under heavy impact. For hail, debris, or vandalism-prone areas, polycarbonate is stronger and safer.

Light Transmission and Clarity

Winner: Polycarbonate

Polycarbonate transmits up to 90% light with near-glass clarity, available in opaque, translucent, or transparent forms. Fiberglass transmits 50–80% diffused light, which suits greenhouses and agricultural uses where even light distribution is beneficial.

UV Resistance and Longevity

Tie: Depends on Quality

Polycarbonate with UV coatings maintains clarity and resists yellowing for 15–25 years. Fiberglass lasts 20–30 years but may yellow, become brittle, or develop “fiber bloom” if UV protection is insufficient.

Chemical and Environmental Resistance

Winner: Fiberglass

Fiberglass excels in chemically harsh, high-moisture environments, resisting ammonia, acids, alkalis, and saltwater. Polycarbonate offers good chemical resistance but is less suited for extreme chemical exposure.

Thermal Performance and Insulation

Winner: Fiberglass

Fiberglass naturally insulates better than solid polycarbonate, helping maintain indoor temperatures. However, multiwall polycarbonate panels provide excellent insulation rivaling fiberglass, suitable when thermal control is critical.

Installation and Handling

Winner: Polycarbonate

Polycarbonate is lightweight, flexible, and easy to cut and drill with standard tools, saving time and labor. Fiberglass is heavier, rigid, and requires specialized tools and more manpower.

Cost Comparison

Most Affordable: Fiberglass

Fiberglass costs less upfront, appealing for budget projects and large installations. Polycarbonate’s higher initial cost often yields better long-term value due to durability and low maintenance.

Maintenance and Repair

Polycarbonate roofing sheets have smooth surfaces that clean easily with mild soap and water. Fiberglass panels’ textured surfaces trap dirt and require more scrubbing. Both materials benefit from regular inspections and timely repairs, which can be done by replacing individual panels, minimizing costs and disruption.

Environmental Considerations

Polycarbonate resists UV rays and extreme temperatures well, making it ideal for outdoor use exposed to sun and weather. Its UV resistance prevents yellowing and degradation, ensuring long-term clarity and durability. Fiberglass may yellow and degrade more under UV exposure but remains durable and cost-effective. Polycarbonate’s recyclability offers an environmental advantage over fiberglass, which is harder to recycle due to its composite nature.

Best Applications for Each Material

Choose Polycarbonate For:

- Skylights and roof glazing requiring maximum light and impact resistance

- Greenhouses where clarity is important

- Security glazing and architectural features needing durability and appearance

- Sports facilities and pool enclosures exposed to extreme weather

Choose Fiberglass For:

- Agricultural buildings and industrial facilities with chemical exposure

- Coastal structures requiring corrosion resistance

- Budget-sensitive projects needing diffused lighting

- Patio covers and carports where cost is a priority

Polycarbonate vs Fiberglass: Making Your Decision

Consider these questions:

Prioritize Polycarbonate If:

- Maximum clarity and impact resistance are needed

- Aesthetics and long-term value are priorities

Prioritize Fiberglass If:

- Chemical resistance and budget constraints are key

- Diffused light is preferred

- The project is industrial or agricultural

Professional Guidance Matters

Both materials perform well when specified and installed correctly. Expert advice ensures optimal material choice, panel thickness, coatings, framing, and installation methods to maximize performance and lifespan.

Ready to start your glazing project? Contact a glazing specialist to discuss your needs and find the best solution.

Crystal Structures Glazing offers expert consultation on polycarbonate, fiberglass, and glass glazing solutions. Contact us to discuss your project requirements.